The Role of Foam Control in Wastewater Treatment: Best Techniques and Methods

The Role of Foam Control in Wastewater Treatment: Best Techniques and Methods

Blog Article

A Comprehensive Overview to Applying Foam Control Solutions in Your Operations

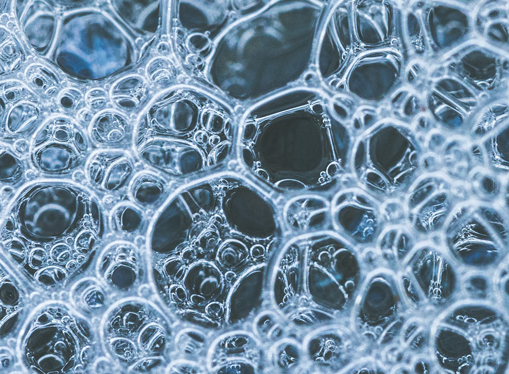

Reliable foam control is an essential element of operational efficiency that frequently goes forgotten. Recognizing the intricacies of foam generation can substantially affect both productivity and product top quality. This overview describes the various challenges presented by foam and the diverse solutions available, providing a framework for choose and carrying out one of the most suitable methods. By examining essential factors such as application compatibility and employees training, organizations can enhance their foam management initiatives. As we check out these parts, the capacity for transformative renovations in your operations comes to be noticeable. What actions will you take next?

Comprehending Foam Difficulties

Foam obstacles are a significant worry throughout different markets, affecting operational performance and item top quality. The development of too much foam can prevent processes such as mixing, transportation, and storage space, resulting in boosted downtime and waste. In fields like food and drink, drugs, and petrochemicals, foam can conflict with assembly line, causing product disparities and contamination risks.

Furthermore, foam can obstruct devices capability, resulting in expensive repair work and maintenance. In wastewater treatment, foam can interfere with clarifier operations, resulting in lower treatment effectiveness and regulative compliance problems.

Recognizing the underlying sources of foam generation is important for efficient monitoring. Factors such as surfactants, temperature changes, and agitation levels can all add to foam production. Identifying these components enables industries to execute targeted techniques that reduce foam formation while keeping product integrity.

Sorts Of Foam Control Solutions

Mechanical solutions involve the use of tools such as foam skimmers or defoamers. Chemical remedies, on the various other hand, include the application of defoaming representatives-- materials that disrupt the foam framework, leading to its collapse. Foam Control.

Lastly, functional approaches concentrate on process changes. This might include customizing equipment specifications, such as temperature level and pressure, or changing the circulation prices of fluids to lessen foam generation. Moreover, executing excellent housekeeping methods can also mitigate foam formation by reducing impurities that add to foam stability.

Picking the ideal foam control service involves examining the particular needs of the operation, consisting of the sort of process, the characteristics of the materials involved, and safety factors to consider.

Picking the Right Products

Choosing the right foam control items needs a comprehensive understanding of the certain application and its one-of-a-kind obstacles. Factors such as the sort of foam, the environment in which it happens, and the wanted result all play crucial roles in product choice. Foam Control. As an example, in sectors like food processing, it is essential to pick food-grade defoamers that abide by security regulations while efficiently managing foam.

In addition, think about the viscosity of the liquid where the foam trouble exists. Some items are developed for low-viscosity applications, while others are customized for thicker fluids. Compatibility with existing procedures is another important aspect; the picked foam control representatives should incorporate perfectly without disrupting total operations.

An additional vital variable is the technique of application. Some products might need dilution, while others can be applied straight. Assessing the convenience of usage and the needed dosage can offer insights right into the have a peek at this site item's effectiveness and useful reference cost-effectiveness.

Application Techniques

Successful application strategies for foam control services call for a methodical method that lines up item selection with functional needs. The very first step includes a complete analysis of the procedures where foam occurs, recognizing particular locations that demand treatment. By engaging cross-functional groups, consisting of production, design, and quality assurance, organizations can collect insights that inform the option of one of the most reliable foam control items.

Next, it is crucial to establish clear goals for foam decrease, ensuring that these objectives are possible and measurable. This might involve defining appropriate foam levels and the timelines for implementation. Training workers on the residential properties and application approaches of selected foam control representatives is just as important, as proper use is vital for optimum outcomes.

Furthermore, integrating foam control services into existing workflows requires careful preparation. Inevitably, a well-structured method will improve operational effectiveness while effectively managing foam-related difficulties.

Surveillance and Evaluating Efficiency

Tracking and examining the performance of foam control solutions is vital for ensuring that implemented techniques produce the preferred outcomes. This procedure entails organized information collection and evaluation to analyze the efficiency of foam control representatives and strategies. Trick efficiency indications (KPIs) need to be developed before application, enabling a clear standard versus which to determine development.

Assessing efficiency likewise needs regular evaluations of foam control procedures and agent efficacy. This can be accomplished through sampling and testing, permitting drivers to establish if existing remedies are satisfying functional requirements. It is vital to get feedback from group participants who communicate with check out this site these systems daily, as their understandings can disclose operational nuances that measurable information may forget.

Eventually, a structured tracking and assessment framework helps identify necessary changes, making certain that foam control remedies continue to be efficient, cost-effective, and lined up with organizational goals.

Conclusion

To conclude, effective foam control remedies are crucial for maximizing operational efficiency and keeping item high quality. An extensive understanding of foam challenges, integrated with the option of proper products and execution methods, helps with the successful monitoring of foam generation. Establishing measurable KPIs and spending in employees training further boost the effectiveness of foam control measures. Routine monitoring and analysis guarantee continual enhancement, ultimately causing a more structured and productive operational setting.

Applying excellent housekeeping methods can additionally reduce foam development by reducing pollutants that add to foam security.

Choosing the ideal foam control items calls for an extensive understanding of the details application and its unique difficulties (Foam Control).Effective execution strategies for foam control solutions need a methodical technique that straightens item selection with operational needs.In final thought, efficient foam control options are crucial for optimizing operational efficiency and maintaining product quality. An extensive understanding of foam difficulties, integrated with the choice of proper items and application methods, assists in the effective administration of foam generation

Report this page